Quality Assurance

At DSN Enterprises, quality is not just a process—it's our commitment. Every gauge we manufacture undergoes rigorous quality control to ensure precision, accuracy, and reliability.

Our Quality Process

A systematic approach ensuring every gauge meets the highest standards

Material Selection

Premium grade OHNS and Tungsten Carbide materials from certified suppliers with full traceability.

Precision Manufacturing

State-of-the-art CNC machining with tight tolerances and skilled craftsmanship.

Heat Treatment

Controlled hardening process achieving 60±2 HRC with sub-zero treatment at -80°C for dimensional stability.

Precision Grinding

High-precision cylindrical and surface grinding to achieve specified dimensions and surface finish.

Inspection & Calibration

Comprehensive dimensional inspection using calibrated instruments traceable to national standards.

Final Verification

100% final inspection and documentation with calibration certificates.

Our Certifications

Recognized by leading industry organizations for our commitment to quality

ISO 9001:2015

Quality Management System certification ensuring consistent quality processes.

API 5B

Licensed manufacturer for threading, gauging, and inspection of casing, tubing, and line pipe threads.

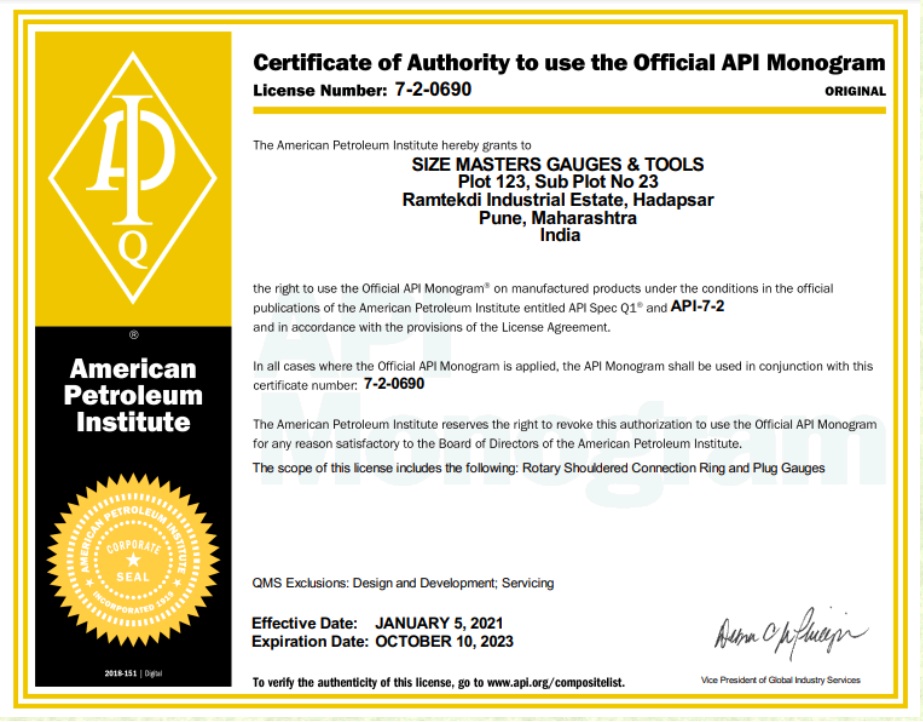

API 7-2

Licensed manufacturer for threading and gauging of rotary shouldered thread connections.

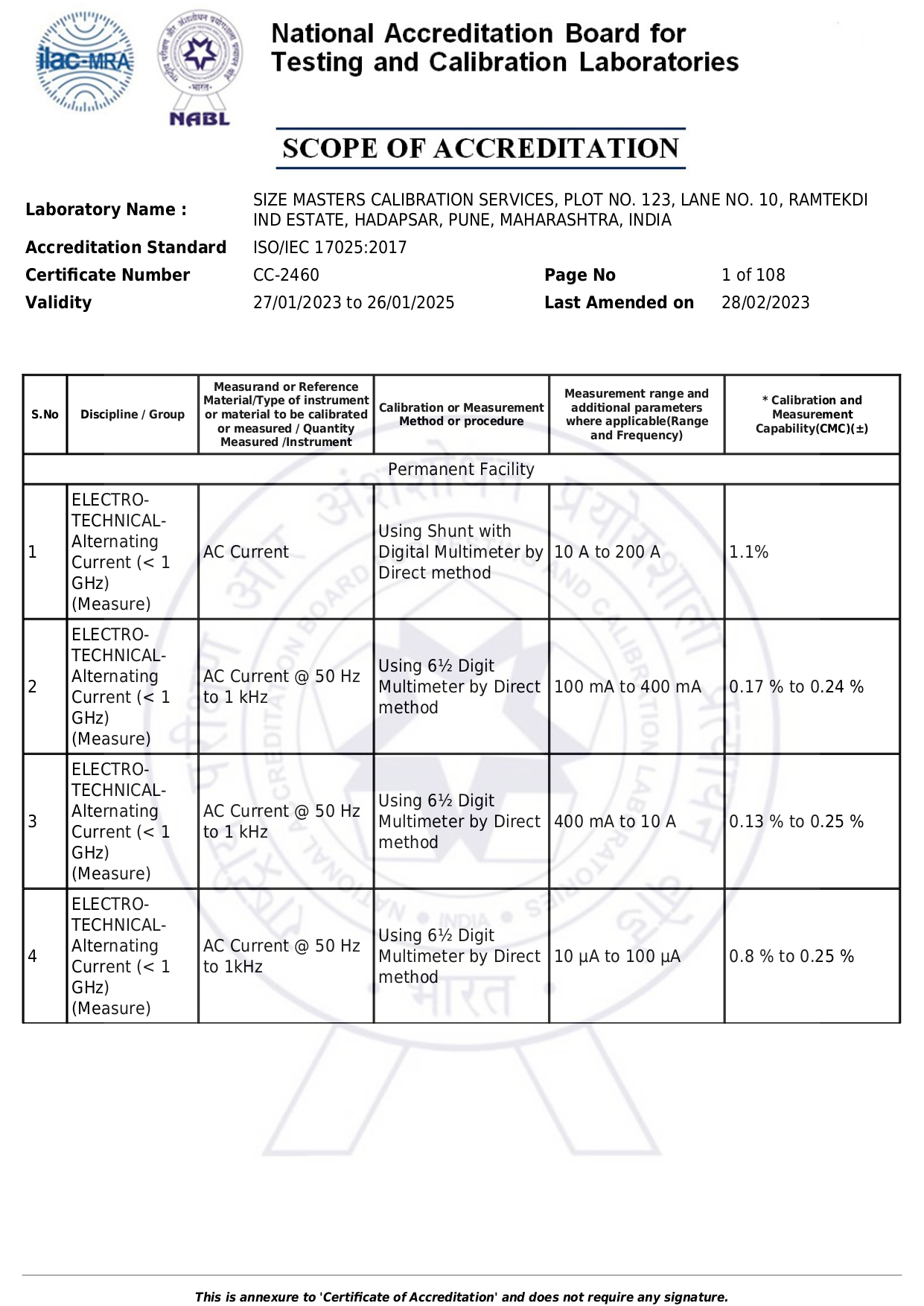

NABL Accreditation

National Accreditation Board for Testing and Calibration Laboratories certification.

Standards We Follow

Manufacturing to international and Indian standards ensures global compatibility

Plain Gauges

- IS 919 (Part 1, Part 2) 1993 - ISO System of Limits & Fits

- IS 3455 - Gauging Practice for Plain Work Pieces

- IS 6244-1980 - Plain Plug Gauges (40mm to 120mm)

- IS 6137-1983 - Plain Plug Gauges (1mm to 40mm)

- IS 3485 - Plain & Master Setting Ring Gauges

- IS 8023 - Single Ended Progressive Type Plate Snap Gauges

Thread Gauges

- IS 6175 - ISO Metric Screw Threads

- IS 4218 - ISO Metric Thread Tolerances

- ANSI/ASME B1.2 - Unified Inch Screw Threads

- BS 84 - BSW/BSF Threads

- BS 21 / ISO 7-1 - Pipe Threads

API Gauges

- API Specification 5B - Threading, Gauging & Inspection

- API Specification 7-2 - Rotary Shouldered Connections

- API RP 7G - Drill Stem Design and Operating Limits

Technical Specifications

| Material | OHNS (W) / Tungsten Carbide |

| Hardness | 60 ± 2 HRC |

| Sub-Zero Treatment | -80°C for dimensional stability |

| Surface Finish | Mirror / Ground finish as specified |

| Tolerance Class | As per IS / ISO / API standards |

| Calibration | Traceable to National/International Standards |

Our Quality Commitment

Need Quality Gauges?

Experience the DSN Enterprises quality difference. Contact us for precision gauges backed by our rigorous quality assurance.